High temperature processes and heat treatment technology

When the best high temperature properties are a requirementExamples from high temperature processes and heat treatment technology

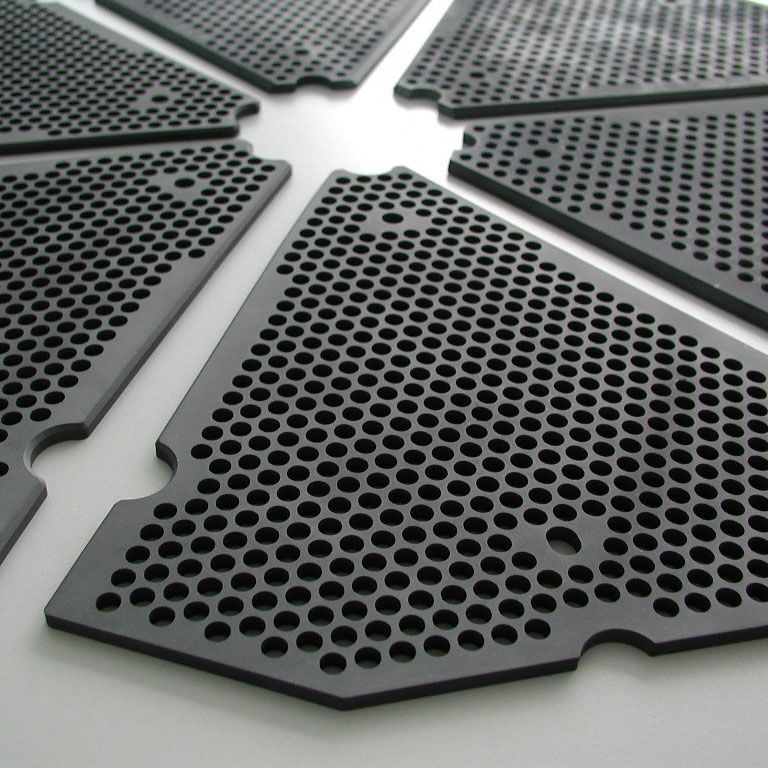

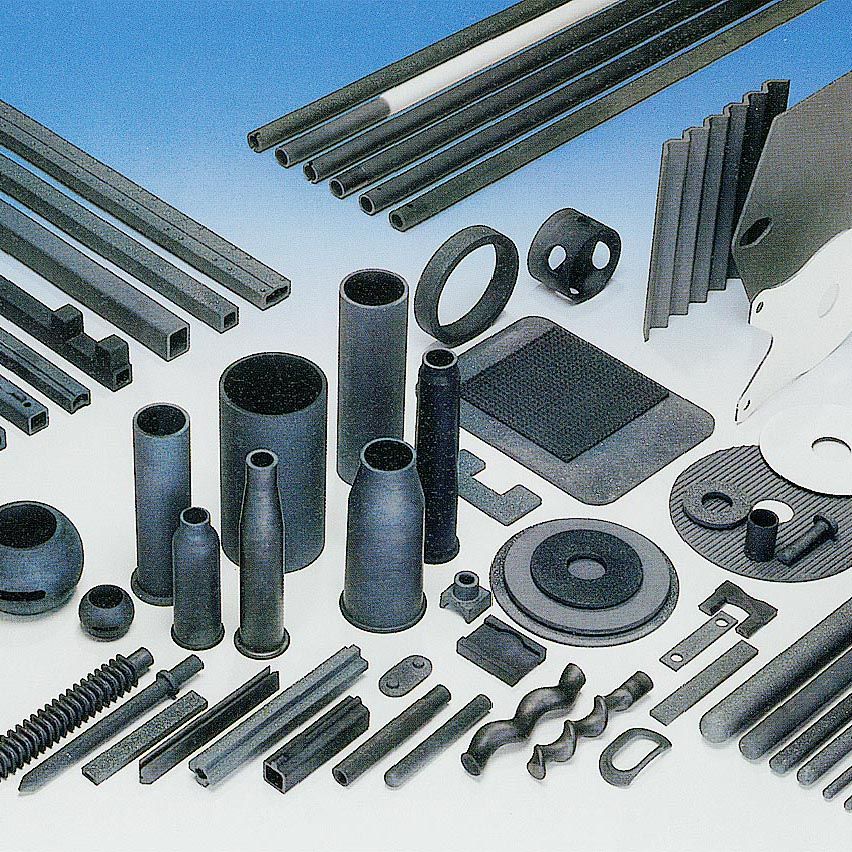

Kiln furniture and setter plates made of silicon carbide or of materials based on silicon nitride not only offer high long-term stability, but also high specific strength. This makes it possible to produce thinner, lighter and more space-efficient kiln furniture, while increasing this way the usable furnace volume and saving some of the energy required to bring the kiln furniture up to temperature. Thanks to the reduced mass of the kiln furniture, faster heating and cooling times may also be achieved, thus improving the heat flow and energy efficiency of the respective high-temperature process. Components made of SSiC also find a good application in corrosive environments, such as heat exchangers and as infrared heaters in high-temperature or flash drying systems, e.g. in the paper industry, as well as in the energy and environmental technology.

Crucibles and crucible holders are suitable for use in the chemical and thermal digestion processes required for element analysis, where a good combination of resistance to corrosion, oxidation and high temperature is required. Components made of silicon nitride or silicon carbide ceramics also find an excellent application in cryogenics, since this group of materials does not become brittle at low temperatures.

The biggest advantages are offered by workpiece holders made of silicon nitride ceramics, which are used for the inductive heating of components in hardening setups. Since no eddy currents are induced in the ceramic holder, only the metal workpiece itself is heated and the loss of energy through the holder and transfer device is minimized. This enables significant energy savings and also long service lives, due to the high wear resistance of the material.